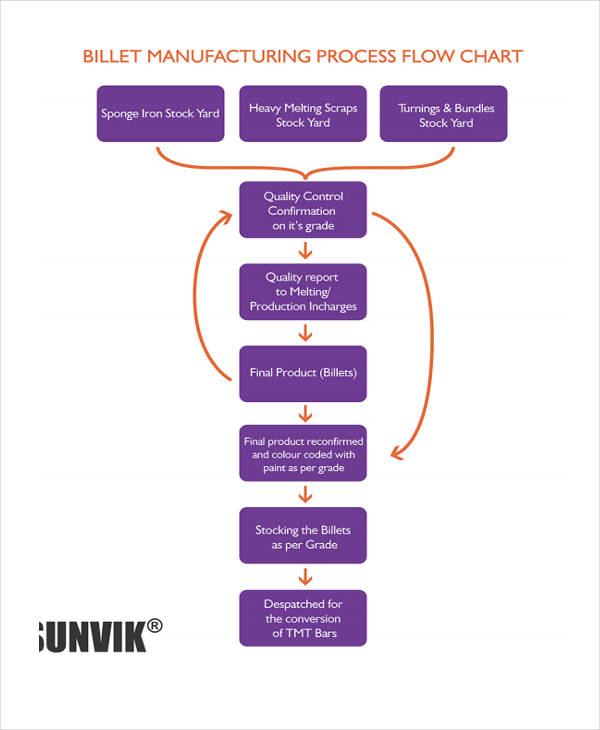

This step includes the generation of the pathogen itself (for subsequent inactivation or isolation of a subunit) or generation of a recombinant protein derived from the pathogen. The first step is the generation of the antigen used to induce an immune response. Summarizes these steps with examples for pathogens that have a licensed vaccine. The manufacture of vaccines is composed of several basic steps that result in the finished product. The approval process consists of four principal elements: New vaccines are subjected to a well-defined regulatory process for approval. Harmonization of regulation continues to progress as joint FDA-EMA establishment inspections programs have become a reality and adherence to International Conference on Harmonisation (ICH) guidance is expected. Impediments to harmonization include lack of standardized regulatory procedures and mutual recognition of licenses and inspections between countries and worldwide regulatory agencies.

Harmonization of licensing and regulating procedures for vaccines worldwide has obvious benefits in rapidly delivering safe and effective vaccines to the market. Human vaccines manufacturing is regulated under a Good Manufacturing Practices (GMP) Directive 200/94/EEC, Annex 16, and Annex 2. Vaccines are licensed through a centralized procedure that allows for simultaneous licensure within all countries within the European Union. The EMA's Committee on Medicinal Products for Human Use through its Vaccine Working Party has oversight for human vaccines. In the European Union, animal and human vaccines are regulated by the European Medicines Agency (EMA), whose main responsibility is the promotion of public and animal health. Vaccines approved for marketing may also be required to undergo additional studies to further evaluate the vaccine and often to address specific questions about the vaccine's safety, effectiveness, or possible side effects. 7 Vaccines undergo a rigorous review of laboratory, nonclinical, and clinical data to ensure safety, efficacy, purity, and potency.

MANUFACTURING PROCESS 3 PDF LICENSE

5, 6 Section 351 of the Public Health Service Act gives the federal government the authority to license biological products and the establishments where they are produced. Current authority for the regulation of vaccines resides primarily in Section 351 of the Public Health Service Act and specific sections of the Federal Food, Drug and Cosmetic Act. Food and Drug Administration's (FDA) Center for Biologics Evaluation and Research (CBER) is responsible for regulating vaccines.

In the United States, vaccines are regulated as biological products. All of this must be accomplished while consistently delivering more than 1 billion doses annually at the relatively low cost of similar therapeutic products. This chapter examines how each of these components is established during the development of a new vaccine and how the field of vaccine manufacturing is responding to emerging challenges for increased capacity (e.g., pandemic influenza vaccine), increased safety assurance (e.g., barrier isolator filling), and increasing complexities of manufacture (e.g., conjugate vaccines). Students should regularly meet with their academic advisor to plan their specific semester schedule to include UNIFI/General Education program and/or university elective hours required.The regulatory authorization to release and distribute the product. University electives may be applied to earn additional academic majors, minors, or certificates. This is a sample plan of study with a suggested sequencing of classes for the major. Manufacturing Engineering Technology: Advanced Manufacturing, B.S.

0 kommentar(er)

0 kommentar(er)